51126/P4

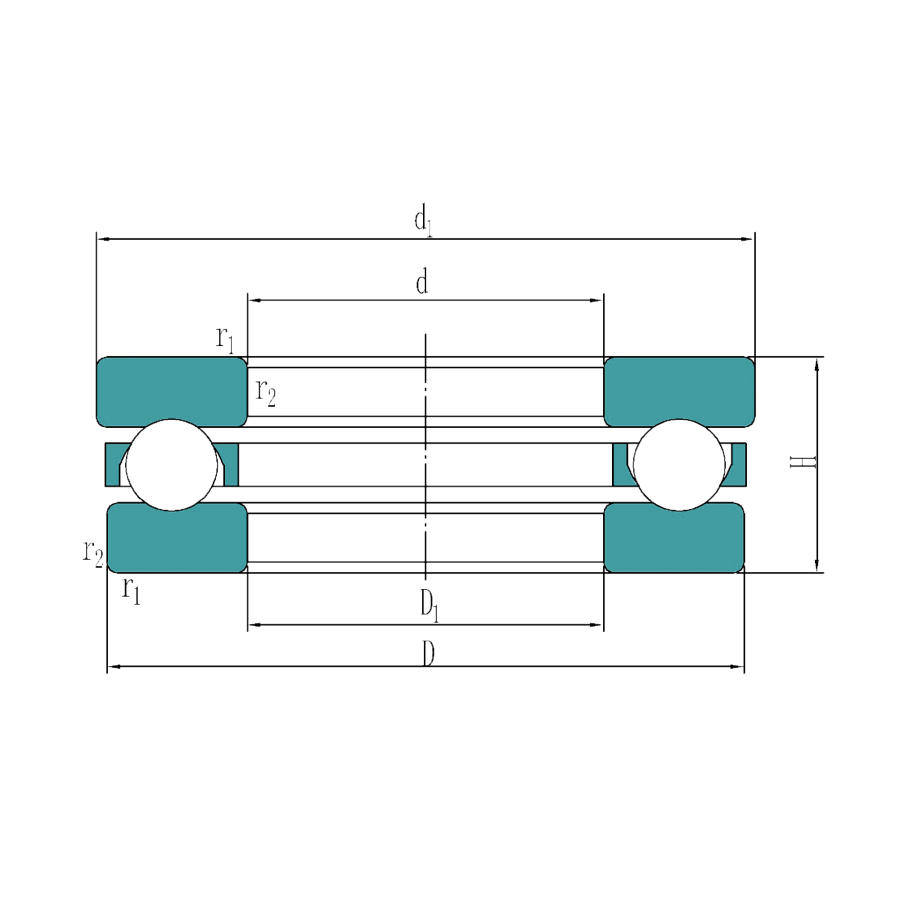

- Внутренний диаметр:

- 130 mm

- Наружный диаметр:

- 170 mm

- Ширина:

- 30 mm

- Масса :

- 1.85 kg

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - 51126/P4

Описание

51126/P4 Характеристики и преимущества упорных шарикоподшипников

Предназначены для осевых нагрузок: Упорные шарикоподшипники специально разработаны для восприятия осевых нагрузок, что обеспечивает уникальные преимущества в этой области.

Возможность самоустановки: Они могут уменьшить влияние ошибок при установке и выдерживать определенную степень осевого смещения.

Разделяемая конструкция: Кольца вала, корпуса и сепаратора могут быть разделены, что делает монтаж и демонтаж подшипников более удобным.

Длительный срок службы: Эти подшипники выдерживают определенный износ и царапины, повышая общую эффективность работы и обеспечивая более длительный срок службы.

Применение: Упорные шарикоподшипники широко используются в кранах, вертикальных насосах, вертикальных центрифугах, домкратах, низкоскоростных редукторах, станках, автомобилях, двигателях и аэрокосмической технике.

QIBR - 51126/P4 Оптимизация упорных шарикоподшипников

Уровни точности: Подшипники могут быть изготовлены с классами точности P4, P6 и P5 в соответствии с требованиями заказчика.

Выбор сепаратора: Тип сепаратора может быть выбран в соответствии с требованиями заказчика, например, штампованный сепаратор или обработанный сепаратор из медного сплава.

Дополнительная настройка: QIBR может разработать и оптимизировать упорные шарикоподшипники в соответствии с условиями использования и требованиями заказчика.

QIBR - 51126/P4 Контроль качества упорных шарикоподшипников

Измерение размеров: Для измерения различных размеров подшипника используется несколько высокоточных приборов с точностью до 0,001 мм.

Точность вращения: Микрометр измеряет небольшие дефекты или отклонения поверхности с точностью измерения до 0,001 мм.

Измерение твердости: Твердомер измеряет поверхностную твердость подшипников с точностью ±0,5HRC.

Металлографический анализ: Профессиональные металлографические микроскопы анализируют внутреннюю металлографическую структуру металлов.

Геометрический допуск: Профильный проектор измеряет геометрическую форму и относительное положение подшипников.

Контроль шума: Виброметры контролируют условия вибрации во время работы для получения данных о шуме.

Контроль сырья: Сталь и детали поставляются от поставщиков, сертифицированных по стандарту ISO 14001, что обеспечивает стабильность продукции и способствует устойчивому развитию.

Особенности и преимущества

Упорные шарикоподшипники обладают такими характеристиками, как компактная структура, малые размеры, небольшой вес, большая нагрузка, износостойкость, водостойкость, защита от загрязнения и термостойкость. Они широко используются во многих областях применения подшипников, таких как механическое оборудование, автомобили, корабли и ветроэнергетика. .

Скачать