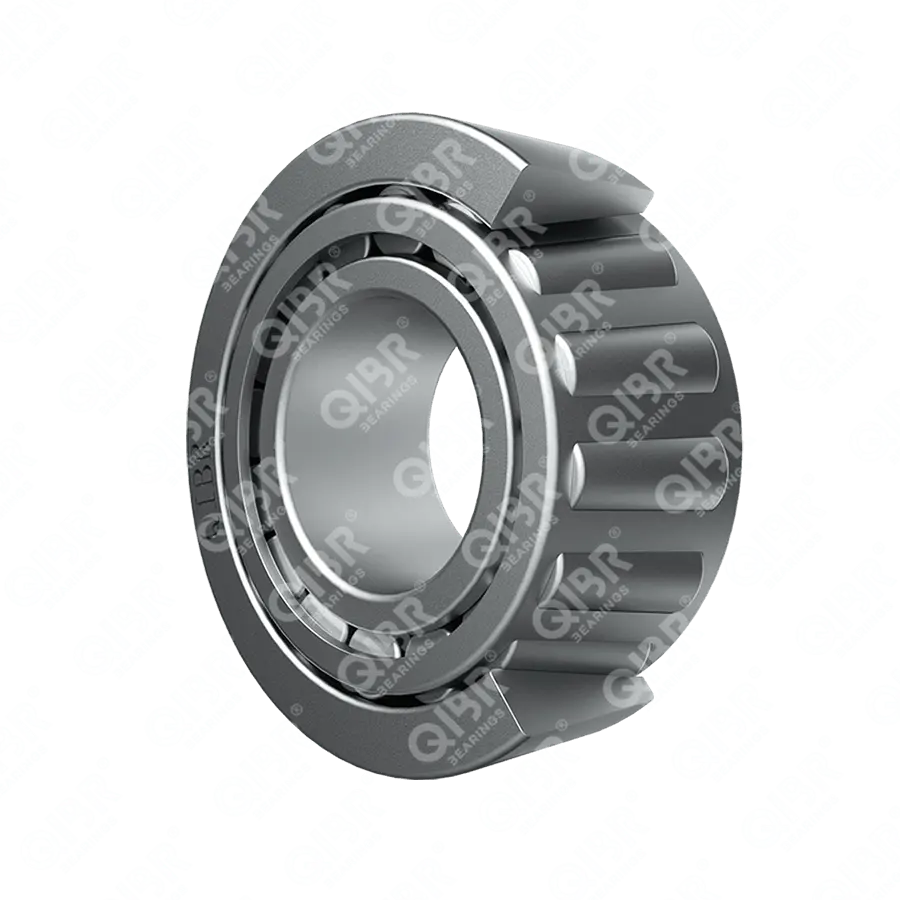

BT2B 332603/HA1

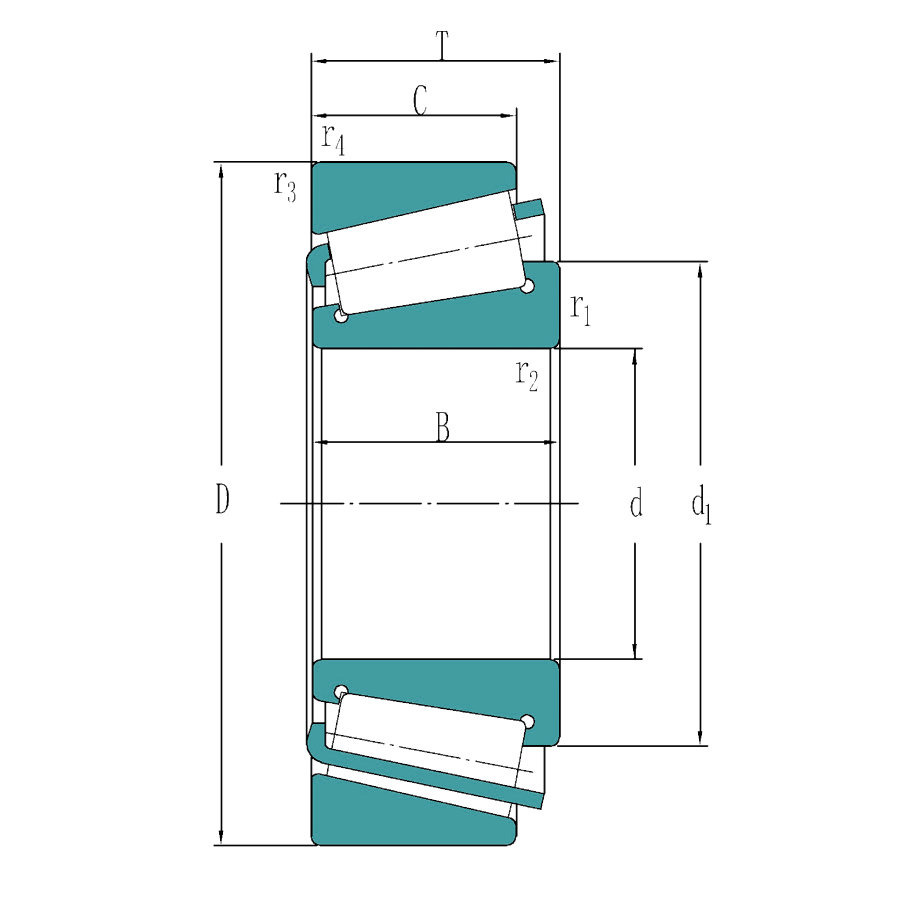

- Внутренний диаметр:

- 368.249 mm

- Наружный диаметр:

- 523.875 mm

- Ширина:

- 214.312 mm

- Масса :

- 140 kg

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - BT2B 332603/HA1

Описание

QIBR - BT2B 332603/HA1 Конический Роликовый Подшипник Advantages and Applications

BT2B 332603/HA1 Конический Роликовый Подшипник, high load-bearing capacity, high rigidity, Bore is 368.249 mm, {$Cup outer diameter (D)$} is {$Cup outer diameter (D)_value$}, {$Bearing width (T)$} is {$Bearing width (T)_value$}, {$Weight$} is {$Weight_value$}, suitable for wheelsets and axle boxes of locomotives, gearboxes and harvesters, etc., and is the most widely used bearing in working conditions with high load-bearing capacity requirements.

QIBR - BT2B 332603/HA1 Конический Роликовый Подшипник Characteristics

BT2B 332603/HA1 Конический Роликовый Подшипник, long life, easy installation and maintenance, strong adaptability. BT2B 332603/HA1 Конический Роликовый Подшипник, can withstand radial load, certain axial load and overturning moment, suitable for mechanical equipment with high durability requirements.

BT2B 332603/HA1 Особенности и преимущества конических роликовых подшипников

Высокая грузоподъемность: Конические роликоподшипники выдерживают значительные радиальные и осевые усилия, что делает их особенно подходящими для восприятия комбинированных нагрузок. Осевая грузоподъемность зависит от угла контакта; чем больше угол контакта, тем больше осевая грузоподъемность.

Высокая точность: Эти подшипники изготавливаются с использованием шлифовальных процессов, что обеспечивает высокую точность, которая необходима для применений, требующих строгих стандартов.

Регулируемый зазор: При установке зазор может быть отрегулирован путем изменения взаимного расположения внутреннего и наружного колец, что оптимизирует рабочие характеристики.

Хорошая жесткость и ударопрочность: Компактная структура конических роликовых подшипников обеспечивает отличную жесткость и превосходную ударопрочность.

Применение: Они широко используются в таких областях, как редукторы, подъемное оборудование, прокатные станы, автомобильная промышленность, металлургия, нефтяная промышленность, горное оборудование, машиностроение и аэрокосмическая промышленность.

QIBR - BT2B 332603/HA1 Оптимизация конических роликовых подшипников

Термообработка: Процесс производства оптимизирован за счет мартенситной закалки (стандарт) и поверхностной закалки термообработки.

Тип сепаратора: Тип сепаратора выбирается в зависимости от требований заказчика и условий эксплуатации, включая такие варианты, как штампованные сепараторы, сепараторы из PA66, армированного стекловолокном, и сепараторы из PEEK.

Специальные варианты: Для особых требований к применению предлагаются подшипники с твердым маслом, изолированные подшипники INSOCOAT и подшипники с износостойким покрытием NoWear.

Больше возможностей для настройки: QIBR может спроектировать и оптимизировать подшипники, основываясь на чертежах и производственных потребностях заказчика.

QIBR - BT2B 332603/HA1 Контроль качества конических роликовых подшипников

Измерение размеров: Для измерения различных размеров подшипников используются различные высокоточные приборы, достигающие максимальной точности 0,001 мм.

Точность вращения: Для измерения незначительных дефектов и отклонений поверхности используется циферблатный манометр с точностью измерения до 0,001 мм.

Измерение твердости: Твердость поверхности измеряется с помощью твердомера с точностью ±0,5 HRC.

Металлографический анализ: Профессиональные металлографические микроскопы используются для анализа внутренней металлографической структуры металла.

Геометрический допуск: Профилемер измеряет геометрическую форму и относительное положение подшипников.

Мониторинг шума: Устройства контроля вибрации оценивают условия вибрации во время работы для получения данных о шуме.

Контроль сырья: Сталь и детали поставляются от поставщиков, сертифицированных по стандарту ISO 14001, что обеспечивает стабильность продукции и способствует устойчивому развитию.

Особенности и преимущества

Конические роликоподшипники обычно являются разъемными, то есть узел конического внутреннего кольца, состоящий из внутреннего кольца с роликами и сепаратора, может быть установлен отдельно от конического наружного кольца (наружного кольца).

Скачать