7012A5TYNDBLP4

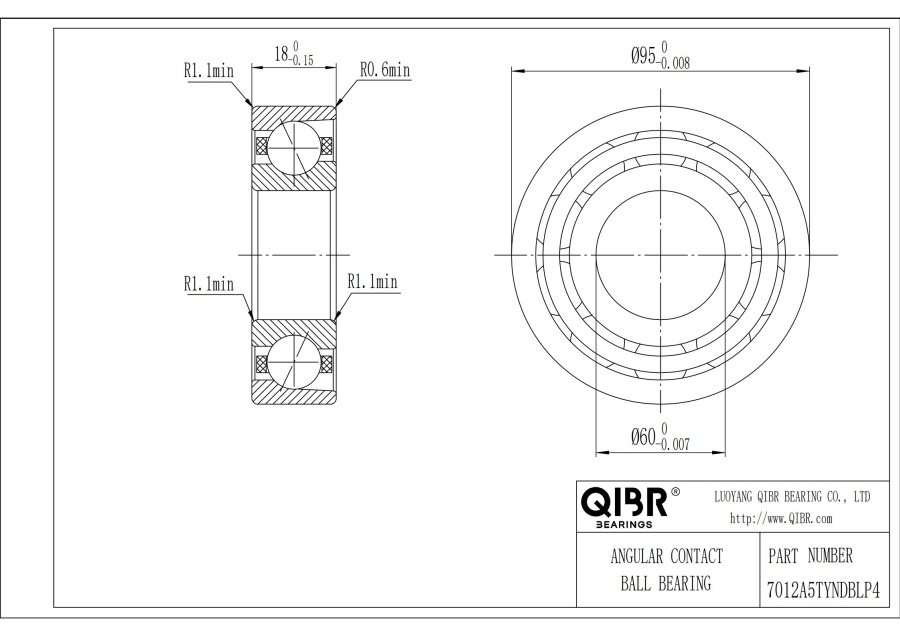

- Внутренний диаметр:

- 60 mm

- Наружный диаметр:

- 95 mm

- Ширина:

- 18 mm

- Масса :

- 0.408 kg

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - 7012A5TYNDBLP4

Описание

QIBR - 7012A5TYNDBLP4 Радиально-Упорный Шариковый Подшипник Преимущества и Применение

7012A5TYNDBLP4 Радиально-Упорный Шариковый Подшипник, низкий уровень шума, высокая скорость,Inner diameter (d) - 60 mm,Outer diameter (D) - 95 mm,Width (B) - 18 mm,Mass - 0.408 kg, подходит для передних колес небольших автомобилей, валов-шестерен дифференциалов, бустерных насосов, буровых платформ и т. д., и является наиболее широко используемым подшипником в условиях, требующих высокой скорости.

QIBR - 7012A5TYNDBLP4 Радиально-Упорный Шариковый Подшипник Характеристики

7012A5TYNDBLP4 Радиально-Упорный Шариковый Подшипник, стабильная работа, не легко повредить, простое обслуживание. 7012A5TYNDBLP4 Радиально-Упорный Шариковый Подшипник, может выдерживать радиальную нагрузку и определенную осевую нагрузку одновременно, подходит для механического оборудования с высокими требованиями к производительности.

7012A5TYNDBLP4 Характеристики и преимущества радиально-упорных шарикоподшипников

Высокая грузоподъемность: Он может выдерживать большие радиальные и осевые усилия, в нем используется высокопрочная сталь и технология точной обработки, обладающая высокой несущей способностью.

Хорошая структурная жесткость: Угол контакта внутреннего и наружного колец большой, структурная жесткость хорошая, и стабильная работа поддерживается при высокой нагрузке.

Высокая точность позиционирования: Внутреннее и внешнее кольца имеют высокую точность совмещения, что позволяет обеспечить точное позиционирование и центрирование.

Высокая скорость работы: Имеет низкий коэффициент трения и высокую скорость, подходит для высокоскоростных операций.

Применение: Имеет широкий спектр применения в станкостроении, автомобилестроении, аэрокосмической промышленности, производстве двигателей и генераторов, робототехнике, медицинском оборудовании, средствах автоматизации и других областях.

QIBR - 7012A5TYNDBLP4 Оптимизация радиально-упорных шарикоподшипников

Дополнительные углы контакта: В зависимости от условий эксплуатации можно выбрать различные углы контакта, например 15°, 18°, 25° или 40°.

Высокоэффективные материалы: Материалы подшипника могут быть заменены в соответствии с различными условиями эксплуатации, при этом могут использоваться такие варианты, как SKF III, ZGcr15, высокочистая подшипниковая сталь, керамика, нержавеющая сталь и другие материалы.

Замена смазки: Выберите смазку в соответствии с рабочими требованиями подшипника, например, LUBCON L252, Multemp SRL или KLUBER ISOFLEX NBU 15.

Оптимизация параметров процесса: Оптимизируйте параметры обработки, такие как скорость шлифования, скорость подачи, глубина резания и т. д., чтобы повысить эффективность и качество обработки.

Больше возможностей для индивидуальной настройки: QIBR может спроектировать и оптимизировать подшипник в соответствии с требованиями заказчика к чертежам и условиям работы подшипника.

QIBR - 7012A5TYNDBLP4 Контроль качества радиально-упорных шарикоподшипников

Измерение размеров: Использование различных профессиональных высокоточных приборов для измерения различных размеров подшипника с максимальной точностью 0,001 мм.

Точность вращения: Используйте микрометр для измерения небольших дефектов или отклонений на поверхности подшипника, с точностью измерения до 0,001 мм.

Измерение твердости: Используйте твердомер для измерения поверхностной твердости подшипника, с точностью измерения до ±0,5HRC.

Металлографический анализ: Используйте профессиональный металлографический микроскоп для анализа внутренней металлографической структуры металла.

Геометрический допуск: Используйте профилометр для измерения геометрии и относительного положения подшипника.

Мониторинг шума: Вибрация во время работы контролируется виброметром для получения данных о шуме.

Контроль сырья: Сталь и детали закупаются у поставщиков, сертифицированных по стандарту ISO 14001, что обеспечивает стабильность продукции и способствует устойчивому развитию.

Процесс и Производительность

QIBR - 7012A5TYNDBLP4 Радиально-упорные шарикоподшипники Процесс и показатели эффективности:

Конструктивные особенности: Кольца изготовлены из подшипниковой стали высокой чистоты путем электрошлакового переплава, в сочетании с бейнитной закалочной термообработкой, криогенной обработкой и технологией модификации материала для уменьшения остаточного аустенита, что значительно повышает усталостную долговечность подшипников этой серии.

Контроль угла контакта: Угол шлифовального круга калибруется с помощью лазерного юстировочного инструмента, с допуском ≤±1′.

Качество поверхности: После суперфинишной обработки шероховатость поверхности составляет Ra ≤ 0,005 мкм, что соответствует требованиям к точности класса P2 (ABEC 7).

Высокоскоростные характеристики: Подшипники с покрытием DLC поддерживают значение dn ≥ 3,5×10⁶ при максимальной скорости вращения 25 000 об/мин (консистентная смазка).

Чистота: Сборка производится в чистом помещении класса 5 по ISO с использованием полностью синтетической авиационной смазки.

Проверка образцов готовой продукции:

- Zeiss PRISMO Ultra (Германия) для полноразмерного трехмерного измерения координат, поддерживающего пространственную точность 0,5+L/350 мкм.

- Проверка угла контакта (α) с точностью ±0,5′.

- Вибрационный тестер подшипников обеспечивает низкий уровень шума и высокую скорость работы (стандарты класса Z4/V4).

Вспомогательные системы и технологическое оборудование: Вакуумное науглероживание с равномерностью слоя науглероживания ≤ ±0,03 мм, что повышает усталостную долговечность подшипника.

QIBR - 7012A5TYNDBLP4 Радиально-упорные шарикоподшипники могут применяться в следующих научно-исследовательских проектах:

- Сверхскоростные шарикоподшипники (внутренний диаметр >6 мм, наружный диаметр <360 мм, коэффициент скорости <4 млн).

- Высокотемпературные высокоскоростные подшипники (внутренний диаметр >6 мм, наружный диаметр <200 мм, рабочая температура <470°C, коэффициент скорости <4 млн).

- Тонкостенные шарикоподшипники (ширина >3,969 мм, наружный диаметр <300 мм).

- Специальные высокотемпературные, низкотемпературные и ударопрочные радиально-упорные шарикоподшипники для шпиндельных систем авиационных двигателей.

- Сверхчистые подшипники для беспыльных цехов.

- Высокожесткие малошумные подшипники для повышения точности шарнирного перемещения.

- Специальные подшипники с функциональными покрытиями.

- Специальные подшипники для труднообрабатываемых материалов.

Как производитель подшипников качения, мы специализируемся на выпуске прецизионных подшипников ABEC 7 P4 и ABEC 9 P2, предназначенных для высокоскоростных и тяжелонагруженных применений. Мы рады предложить лучшие решения, используя наш опыт.

Что означают буквы префикса радиально-упорных шарикоподшипников?

Буквы префикса радиально-упорных шарикоподшипников зависят от бренда. Например:

Швеция SKF 7012A5TYNDBLP4:

- C = гибридные керамические шарикоподшипники,

- S = подшипники с уплотнениями,

- SC = уплотненные с уклонами на внутреннем и наружном кольцах.

Германия FAG 7012A5TYNDBLP4:

- B = стандарт,

- HCB = стандартные керамические шарики,

- XCB = сверхдолговечные стандартные керамические шарики,

- RS = стальные шарики для высокоскоростных подшипников,

- HCRS = керамические шарики для высокоскоростных подшипников,

- HS = стальные шарики для малых шарикоподшипников,

- HSS = стальные шарики для малых шарикоподшипников с уплотнениями,

- HC = керамические шарики для малых шарикоподшипников,

- HCS = керамические шарики для малых шарикоподшипников с уплотнениями,

- XC = сверхдолговечные малые керамические шарики,

- XCS = сверхдолговечные керамические шарики с уплотнениями.

Что означают буквы суффикса угла контакта в радиально-упорных шарикоподшипниках?

Суффиксные буквы для обозначения угла контакта зависят от марки. Например:

- Швеция SKF 7012A5TYNDBLP4:

- CD = стандартный угол контакта 15°,

- ACD = стандартный угол контакта 25°,

- CE = высокоскоростной угол контакта 15°,

- FE = высокоскоростной угол контакта 18°,

- ACE = высокоскоростной угол контакта 25°,

- CB = угол контакта 15° в B-структуре,

- FB = угол контакта 18° в B-структуре,

- ACB = угол контакта 25° в B-структуре.

- Германия FAG 7012A5TYNDBLP4:

- C = угол контакта 15°,

- D = угол контакта 20°,

- E = угол контакта 25°.

- Япония NSK 7012A5TYNDBLP4:

- C = угол контакта 15°,

- A5 = угол контакта 25°,

- A = угол контакта 30°.

Что означают суффиксные буквы преднатяга в радиально-упорных шарикоподшипниках?

Суффиксные буквы для обозначения преднатяга зависят от марки. Например:

- Швеция SKF 7012A5TYNDBLP4:

- GA = универсальный одинарный легкий преднатяг,

- GB = универсальный одинарный средний преднатяг,

- GC = универсальный одинарный тяжелый преднатяг,

- GD = универсальный одинарный сверхтяжелый преднатяг.

- Германия FAG 7012A5TYNDBLP4:

- L = легкий преднатяг,

- M = средний преднатяг,

- H = тяжелый преднатяг.

- Япония NSK 7012A5TYNDBLP4:

- L = легкий преднатяг,

- M = средний преднатяг,

- H = тяжелый преднатяг.

Что означают буквы суффикса типа сепаратора в радиально-упорных шарикоподшипниках?

Суффиксные буквы для обозначения типа сепаратора зависят от марки. Например:

- Швеция SKF 7012A5TYNDBLP4:

- Default = фенольная смола,

- MA = латунь,

- TNHA = PEEK.

- Япония NSK 7012A5TYNDBLP4:

- TYN = нейлон,

- TR = фенольная смола.

Что означают буквы суффикса для тел качения в радиально-упорных шарикоподшипниках?

Суффиксные буквы для тел качения зависят от марки. Например:

- Швеция SKF 7012A5TYNDBLP4:

- HC = керамические шарики,

- Default = стальные шарики.

- Япония NSK 7012A5TYNDBLP4:

- SN24 = керамические шарики.

Что означают буквы суффикса класса точности радиально-упорных шарикоподшипников?

Суффиксные буквы для обозначения класса точности зависят от марки. Например:

- Швеция SKF 7012A5TYNDBLP4: P4, P4A, P2, PA9A.

- Германия FAG 7012A5TYNDBLP4: P5, P5S, P4, P4S, P2.

- Япония NSK 7012A5TYNDBLP4: P2, P4, P5.

Что означают буквы суффикса количества комплектов подшипников в радиально-упорных шарикоподшипниках?

Суффиксные буквы количества комплектов подшипников зависят от марки. Например:

- Швеция SKF 7012A5TYNDBLP4:

- D = два подшипника,

- T = три подшипника,

- Q = четыре подшипника,

- P = пять подшипников.

Суффиксные буквы для метода сопряжения в радиально-упорных шарикоподшипниках

Суффиксные буквы для метода сопряжения зависят от марки. Например:

- Швеция SKF 7012A5TYNDBLP4:

- B = спина к спине,

- F = лицом к лицу,

- T = тандем,

- BT = спина к спине тандем,

- FT = лицом к лицу тандем,

- BC = спина к спине спаренная,

- FC = лицом к лицу спаренная.

- Германия FAG 7012A5TYNDBLP4:

- U = универсальный одинарный,

- DU = два универсальных одинарных,

- DB = спина к спине,

- DT = тандем,

- DF = лицом к лицу,

- TU = три универсальных одиночных,

- TBT = тройной совпадающий,

- TT = тройной совпадающий,

- TFT = тройной совпадающий,

- QBC = четверной совпадающий,

- QFC = четверной совпадающий,

- QT = четверной совпадающий,

- QBT = четверной совпадающий,

- QFT = четверной совпадающий,

- PBC = пятерной совпадающий,

- PFC = пятерной совпадающий,

- PT = пятерной совпадающий,

- PBT = пятерной совпадающий,

- PFT = пятерной совпадающий.

- Япония NSK 7012A5TYNDBLP4:

- SU = универсальный одинарный,

- DU = два универсальных одинарных,

- DB = спина к спине,

- DF = лицо к лицу,

- DT = тандем,

- DBD = тройное соответствие,

- DFD = тройное соответствие,

- DTD = тройное соответствие,

- DBB = четверное соответствие,

- DFF = четверное соответствие,

- DBT = четверное соответствие,

- DFT = четверное соответствие,

- DTT = четверное соответствие.

Суффиксные буквы для обозначения типа подшипника в радиально-упорных шарикоподшипниках

Суффиксные буквы для обозначения типа подшипника зависят от марки. Например:

- Германия FAG 7012A5TYNDBLP4:

- T = направляемое наружное кольцо из фенольной смолы,

- DLR = кольцевая канавка с просверленными отверстиями и уплотнительным кольцом,

- 2RSD = двусторонние уплотнения.

Особенности и преимущества

Подшипники шпинделя отличаются высокой точностью, жесткостью, низким коэффициентом трения и высокой скоростью, что обеспечивает плавную работу, повышенную точность обработки и длительный срок службы. Они широко используются в станках, промышленных роботах и высокоскоростном вращающемся оборудовании.

Скачать